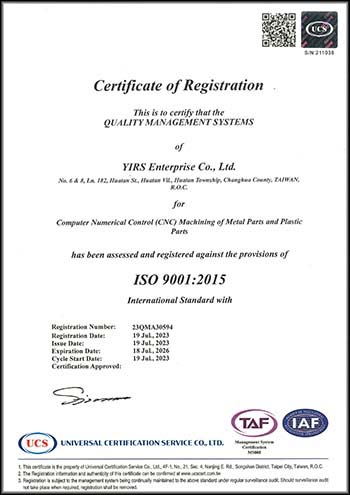

Perfect quality comes from taking into details throughly, YIRS starts from raw material inspection, process arrangement, mechanical precise process to finished product inspection. Each procedure must undergo professional testing and strict quality control to ensure that YIRS products meets and even exceed quality standard before leaving the factory. This is how we keep the consistency of the highest quality.

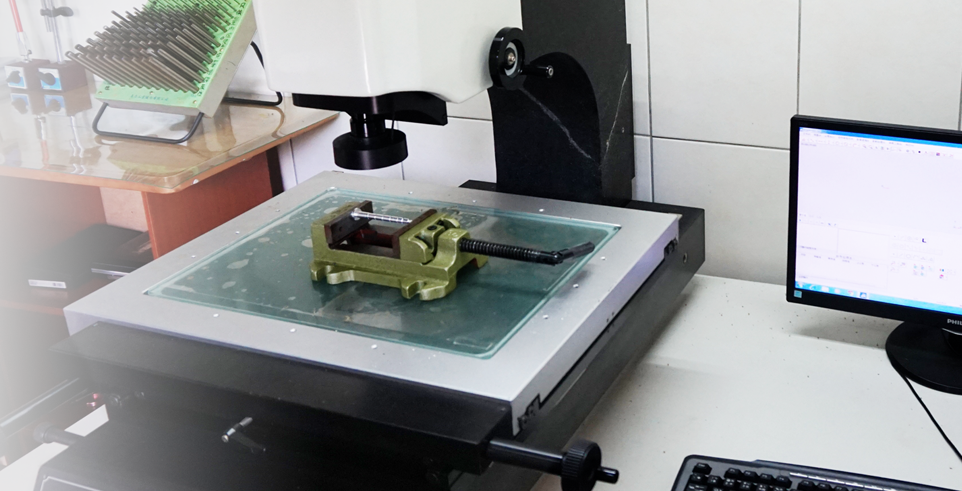

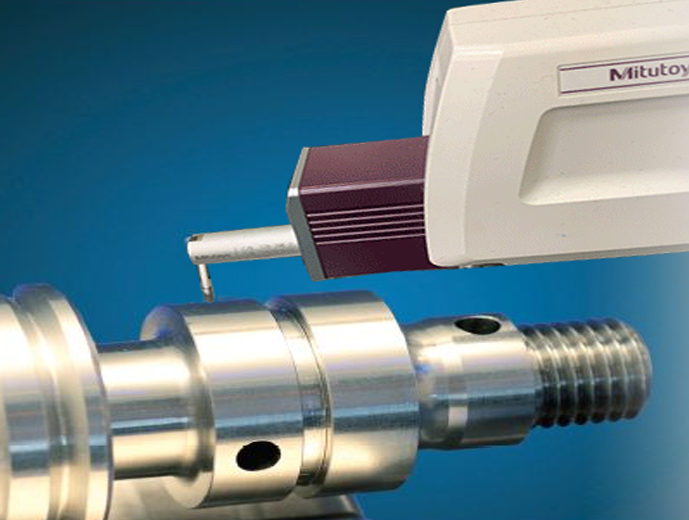

In order to ensure and strengthen the quality control system, we use highly reliable testing instruments, including advanced CMM three-dimensional Coordinate Measuring Machine, 2.5D Manual Vision Measuring Machine, electronic height gauge, film thickness measuring instrument, surface roughness measuring instrument, and all kinds of precision tooth gauges etc. Our professional QC personnel strictly focus on the quality control of every precision product to ensure the highest precision and quality of parts and products for our customers.

Quality